Potato Store Temperature

Potato Storage Tecnology involves: the processes of drying, curing and storing Potatoes.

1. The drying process of potatoes.

The objective of the drying process of potatoes is to remove all superficial moisture keeping the potato humid.

The “drying” of potatoes is a very delicate process, because, in fact, we don’t want to dry them, but to remove the excess of moisture from the tuber and the soil that came with the potatoes into the storage. The “drying” is done preferably at a temperature of about 25°Celsius and aRelative Humidity of about 85%. In some extreme situations humidifiers are used during the drying of potatoes, otherwise a result as shown in the picture to the right will be the case.

It can be stated that the potatoes are “dry” when there isn’t any noticeable moisture, but the tuber has not a “humid”, but: “cool”touch.

2. The curing process of potatoes.

The curing of potatoes is a process where the potatoes are kept for a prolonged period (7 to 10 days) at 15°Celsius and aRelative Humidity of around 95%. Under these circumstances the potatoes are given an opportunity to auto-heal its small skin lesions, incurred during harvesting, transport and storing. This healing is done to improve the tubers storability. No more open “wounds” in contact with the outside, so less chance of infection during storage.

It will be understood that for a correct curing process, an adequate Humidification Systems is required.

Be Aware! : If there is the slightest possibility of a Phytophthora (Potato Late Blight) infection, the curing process must be discarded and the tubers should be brought as soon as possible to their required storage temperature.

3. Lowering the temperature of the potatoes.

After the drying and possible curing of the potatoes, the cooling down to the required storage temperature (see below) process is started. This should be done in such a way that the potatoes lose as little weight as possible and should be done gradually.

The day per day temperature decrease should NOT exceed 0.3 to 0.5°Celsius.

Very important: Under NO circumstances should the temperature increase during this process. A potato that is being cooled down, “thinks” it is going toward winter, but if all of the sudden the temperature increases it’s sprouting mechanism is triggered because the potato now “thinks” it is becoming summer again.

The air used for cooling should have a sufficient cooling capacity but the temperature of the cooling air should not be more than 2°Celsius cooler than the potatoes. And during this whole process the air used should be sufficiently humid (around 85% Relative Humidity).

This delicate cooling down process of potatoes , where a delicate “dance” of the hedges, condensers , humidification installations and a constant monitoring of different temperatures and humidity’s are involved is totally automated (“choreographed”) through the MULTISERVER.

4. The storage temperatures of potatoes.

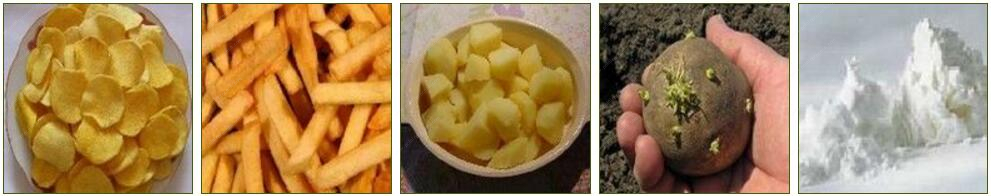

The final destination of the potato determines its storage temperature.

Below the recommended storage temperatures and relative storage humidities for potatoes according their final destination.

- Potatoes for CHIPS 7° to 10°Celsius Relative Humidity 90%.

- Potatoes for French Fries5° to 6°CelsiusRelative Humidity 90%.

- Table (fresh) Potatoes4° to 7°CelsiusRelative Humidity 90%.

- Seed Potatoes 4° to 5°Celsius Relative Humidity 90%.

- Potatoes for Potato Starch 4° to 5°CelsiusRelative Humidity 90%.

The Maillard reaction. :The moment potatoes are cooled below 5° to °8 Celsius the starches are turned into sugars, the so-called Reducing Sugars. These reducing sugars are the main cause of the brownish discoloration, bitter taste and flabby consistency of Potato Chips and French Fries if the re-warming of the potatoes after storage is done incorrectly. This called the Maillard reaction.

5. Increasing the temperature of the potatoes after storage.

After storage, the potatoes should be warmed up for two reasons:

- To give the Reducing Sugars, formed during the time the potatoes were below °8 Celsius, the time to reconstitute back to starch to avoid the Maillard reaction.

- Those potatoes that go to the fresh market should be raised in temperature to avoid condensation in the market place.

This process of increasing the temperature of the potatoes at the end of the storage period is nearly the exact reverse of the process of decreasing the temperature. Again it is completely automated or choreographed by a special program of theMULTISERVER.

6. The sprouting or germination of potatoes during storage.

Potatoes stored below 5° Celsius will not sprout. The higher the storage temperature, the more sprouting or germination may become a serious problem. Various commercial products in the form of gases and powders exist that can be of great help avoiding the sprouting of the tubers.

Company Profile

Adhering to the principle of managing scientifically and honesty and credit,our factory has passed ISO9001-2000 quality system certification. Now, Our factory can provide potato dry cleaning machine, automatic potato washing peeling machine, potato peeling machine, french fries sticks cutting machine, potato grader, potato cleaning and sorting machine, potato chips production line, french fries production line, frozen french fries production line, wave shape french fries production line, potato starch production line, potato mesh bag packing machine, potato dosing packing machine.

Our potato processing products have passed with CE,ISO and SGS Certificates and has been widely sold all over the world